Mechanical Engineering Experience

I love tackling engineering challenges by looking at the big picture—finding solutions that are technically sound, practical, and impactful.

Master’s Thesis - Print path optimization for high strength-to-weight ratio carbon-fiber structures.

Mechanical Design Engineer for Suspension parts, Chassis Assembly, Actuation Systems, and Aerodynamic Bodywork

Scroll to explore

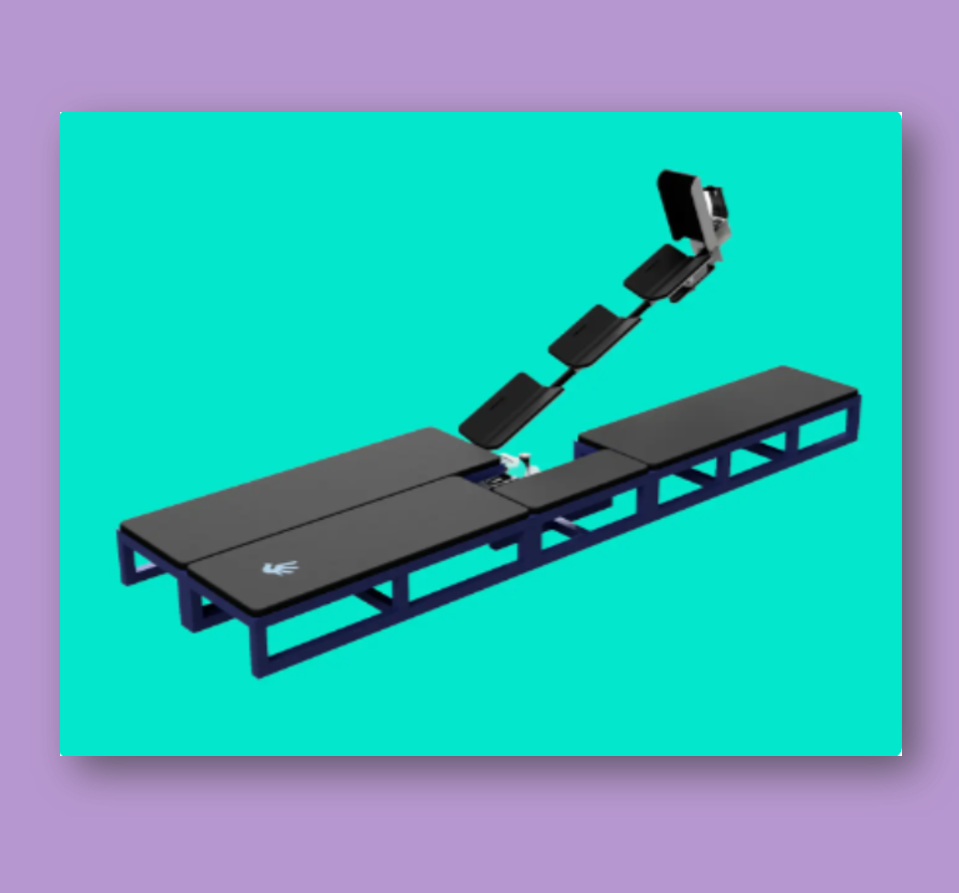

Hamstring Stretching Device

Heat Sink - Cold plate design and experimental validation on NVIDIA’s Blackwell GPUs

Internship experience: A device, that improved patient physiotherapy health outcomes while reducing labor for rehab services.

A small Intro to me!

Hello! I hope you’re enjoying learning about my projects! I'm super passionate about product design, consumer electronics, and automotive-sustainable engineering. I'm always on the lookout for opportunities that create innovative user experiences and a positive impact altogether.

If you’re a recruiter/hiring manager, I’d love to connect as I’m on the lookout for full-time roles as a Mechanical Engineer!

Contact: pranav21kashide@gmail.com

Research Projects

-

Thermal - Fluid Film Cooling of a Gas Turbine engine

Numerical Analysis of Jet-Film Cooling over a GasTurbine End-wall

-

Aeropropulsion Laboratory

Hands-on experimentations to validate computational results

-

Data Analysis & Prediction using conditional Dynamic Mode Decompostion

Constrained Dynamic Mode Decomposition (DMDc) to analyze vortex shedding in 2D flow over an oscillating cylinder using python

Recently took up the Six Sigma: Green Belt training and found it to be very useful!