Formula Student Hybrid 2019

Since 2006, the Thayer School of Engineering at Dartmouth University has hosted the annual Formula Hybrid competition at New Hampshire Motor Speedway. University students design and build hybrid or electric racecars for various challenges.

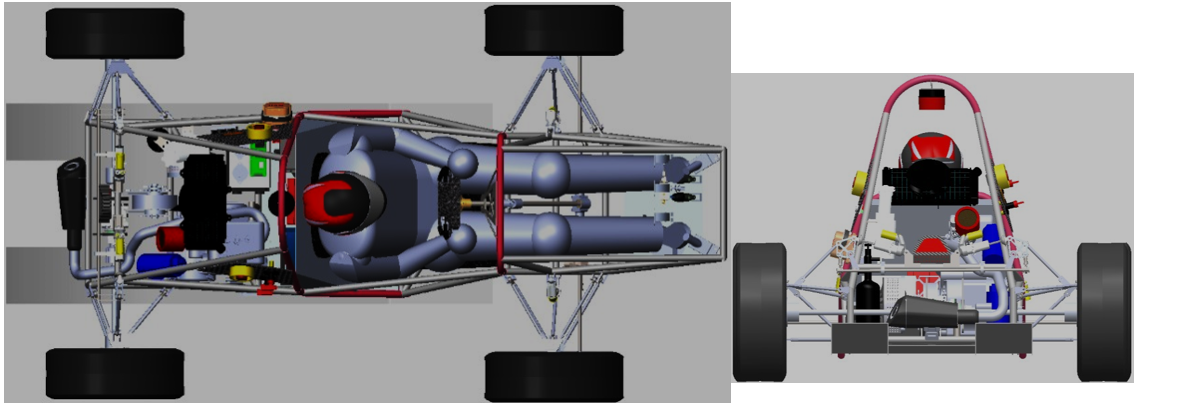

During my tenure with Team Uttejit, I was responsible for suspension parts, actuation systems, chassis assembly, and aerodynamic bodywork.

Tools Applied: Finite Element Analysis, CAD software, collaboration with suppliers, CNC machining, pneumatic actuator systems.

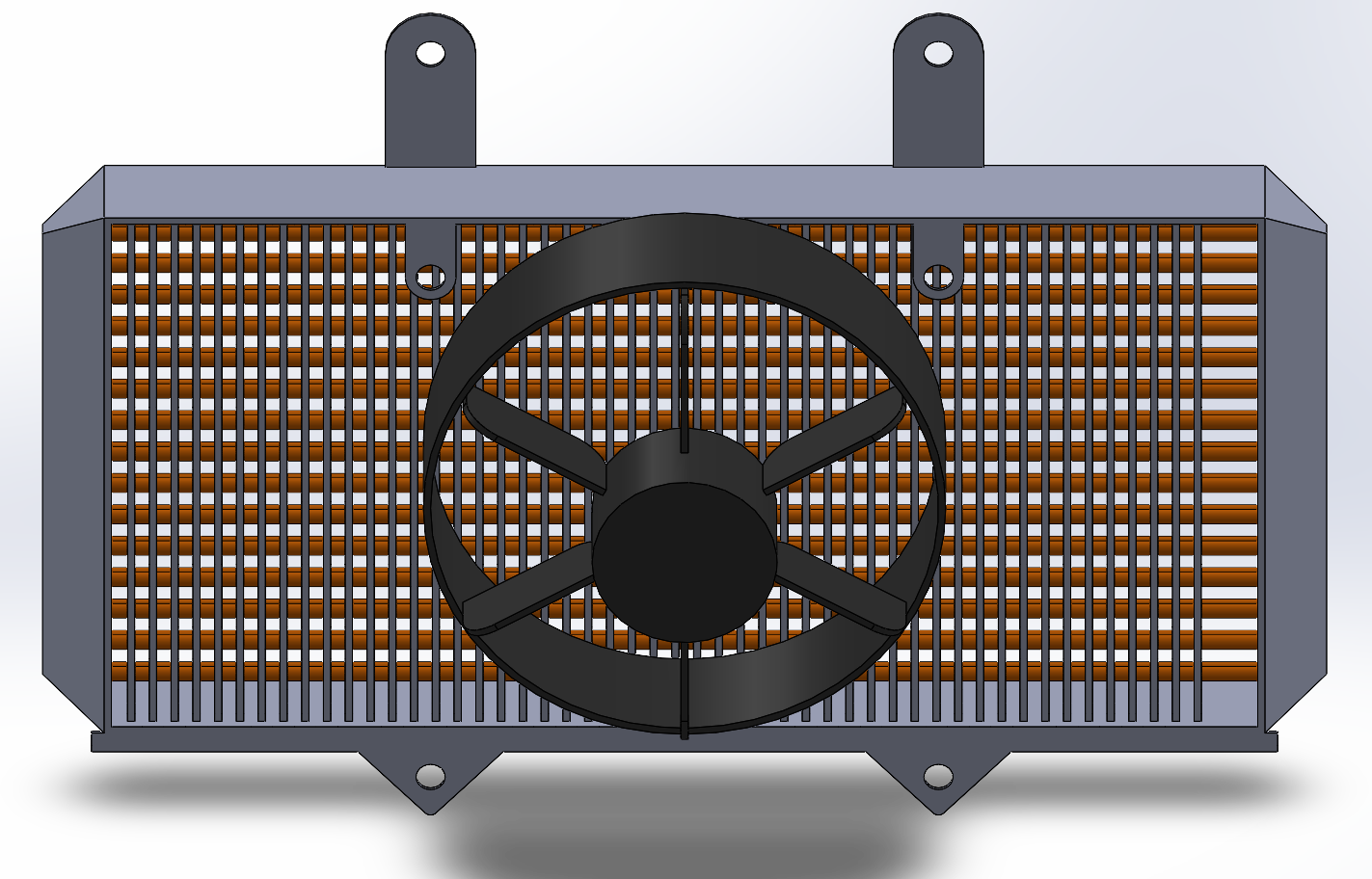

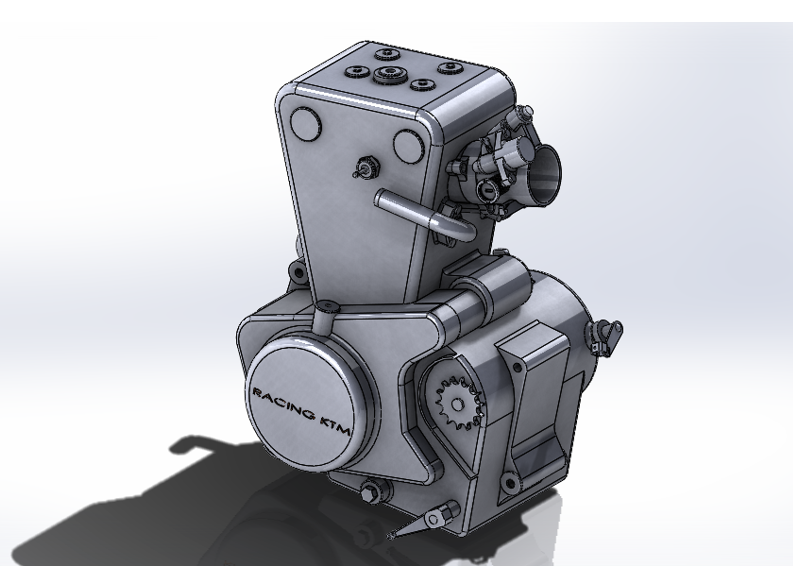

I began by honing my CAD skills by designing various component-level automotive products, such as electric motors, engines, radiators, and pumps.

I then owned the design and manufacturing of suspension uprights, chassis assembly, DRS, and bodywork.

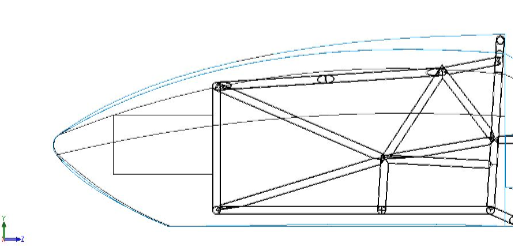

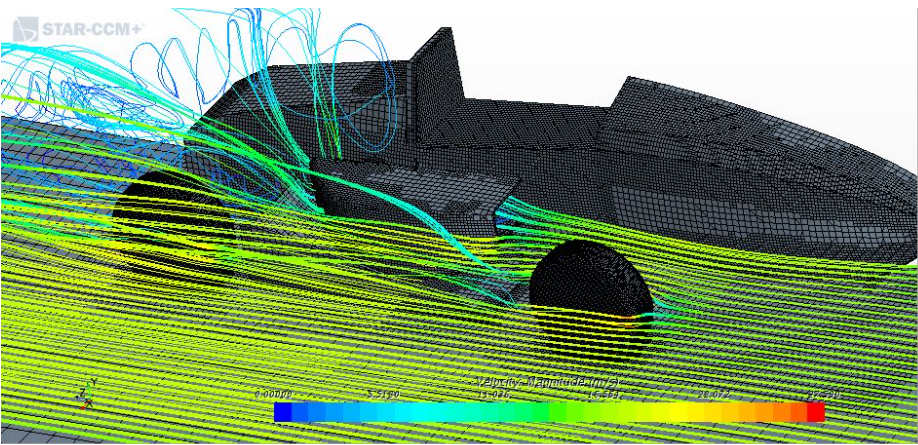

I was tasked with designing an aerodynamic nose cone and side pods that efficiently channeled air to the cooling system via the radiator (enclosed in the side pods). The images highlight my significant work in managing the turbulent airflow from the front wheels.

By incorporating different guide vane designs, I effectively slowed the air to optimize convection through the radiator fins, ensuring effective cooling without substantially increasing drag.

I engineered the mounting and operational design for a rear-wing drag reduction system (DRS) utilizing a pneumatic actuator-controlled aerodynamic flap.

Electric Motor

I assisted in experimental crash safety testing on an aluminum honeycomb attenuator vs. Impax foam using a Universal Testing Machine, assessing energy absorption and quasi-static impact loading conditions. Lastly, I worked with cross-functional teams (suspension, powertrain, chassis) to bring all CAD models into a single assembly of the vehicle, making sure everything fit seamlessly.

As a Mechanical Design Team Lead for the next season, I directed the team in redesigning the chassis fixture table and aerodynamic bodywork to optimize performance and reduce material usage by reusing suspension parts, earning 1st rank in Asia at ISIE HVC 2020.

Single Cylinder Engine

Radiator

Suspension Uprights

Suspension Uprights

Suspension uprights are vital to rigidly transfer the loads from the tires and brakes to the suspension system.

Design Considerations: My design plan for this part includes completing load transfer calculations, running topology optimization, and then using optimized geometry for two different materials 6061 vs. 7075-T6 Al alloys while maintaining an FOS of 1.3. The feasible choice of material was decided such that it avoided re-manufacturing costs due to failures that were incurred during our last season.

The main result of this project is the upright design that can provide the necessary stiffness to the system while simultaneously guaranteeing the pilot's safety and suspension reliability.