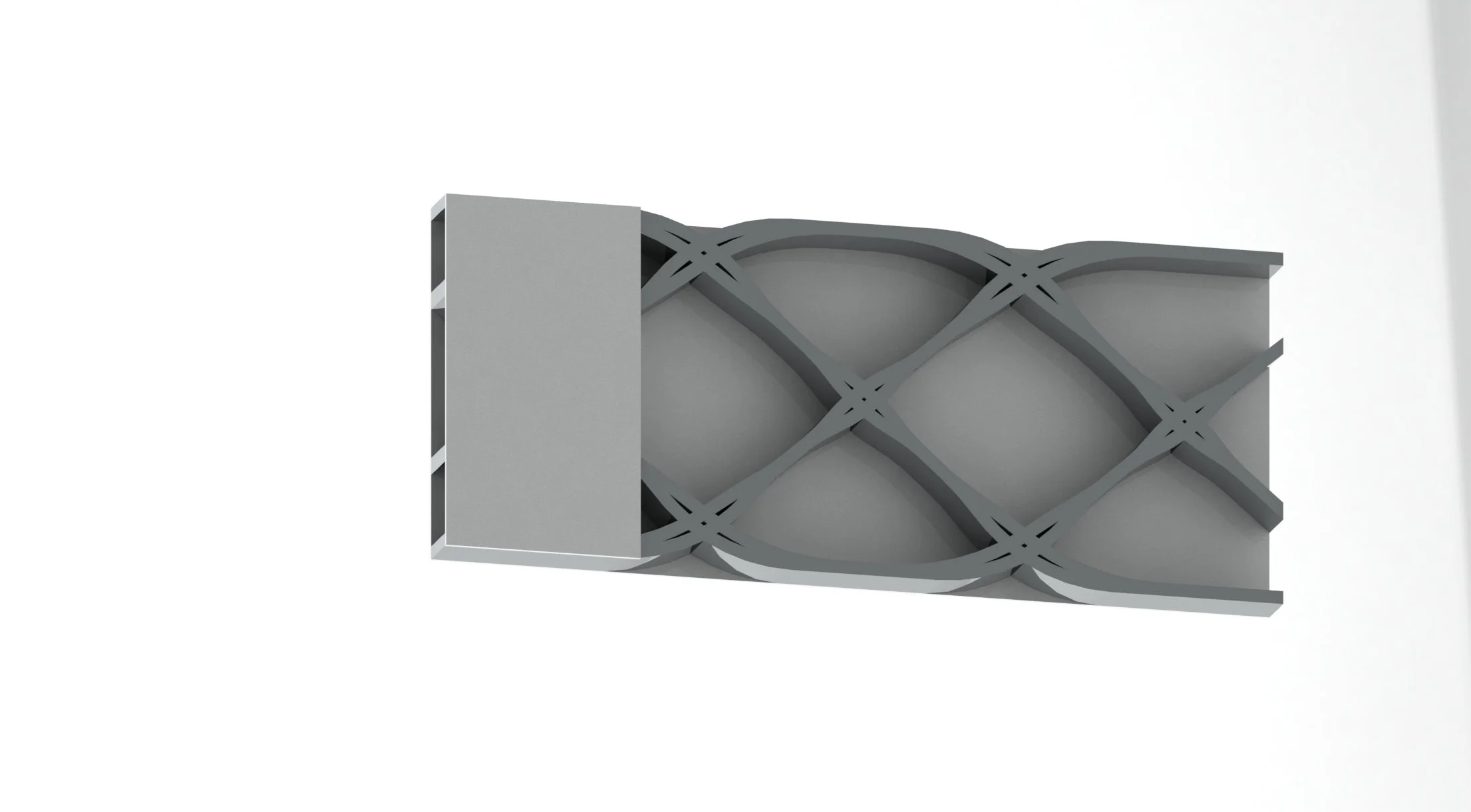

In our ongoing quest to create lighter and stronger materials, especially for demanding fields like aerospace and automotive engineering, we’ve come up against the limitations of traditional sandwich composite structures. These structures, while effective, rely on independent cure cycles for core and skins, as well as adhesive bonding between core and skins, which can restrict their potential.

Continuous Fiber Additive Manufacturing using Dual UV-Thermal Curing Polymer

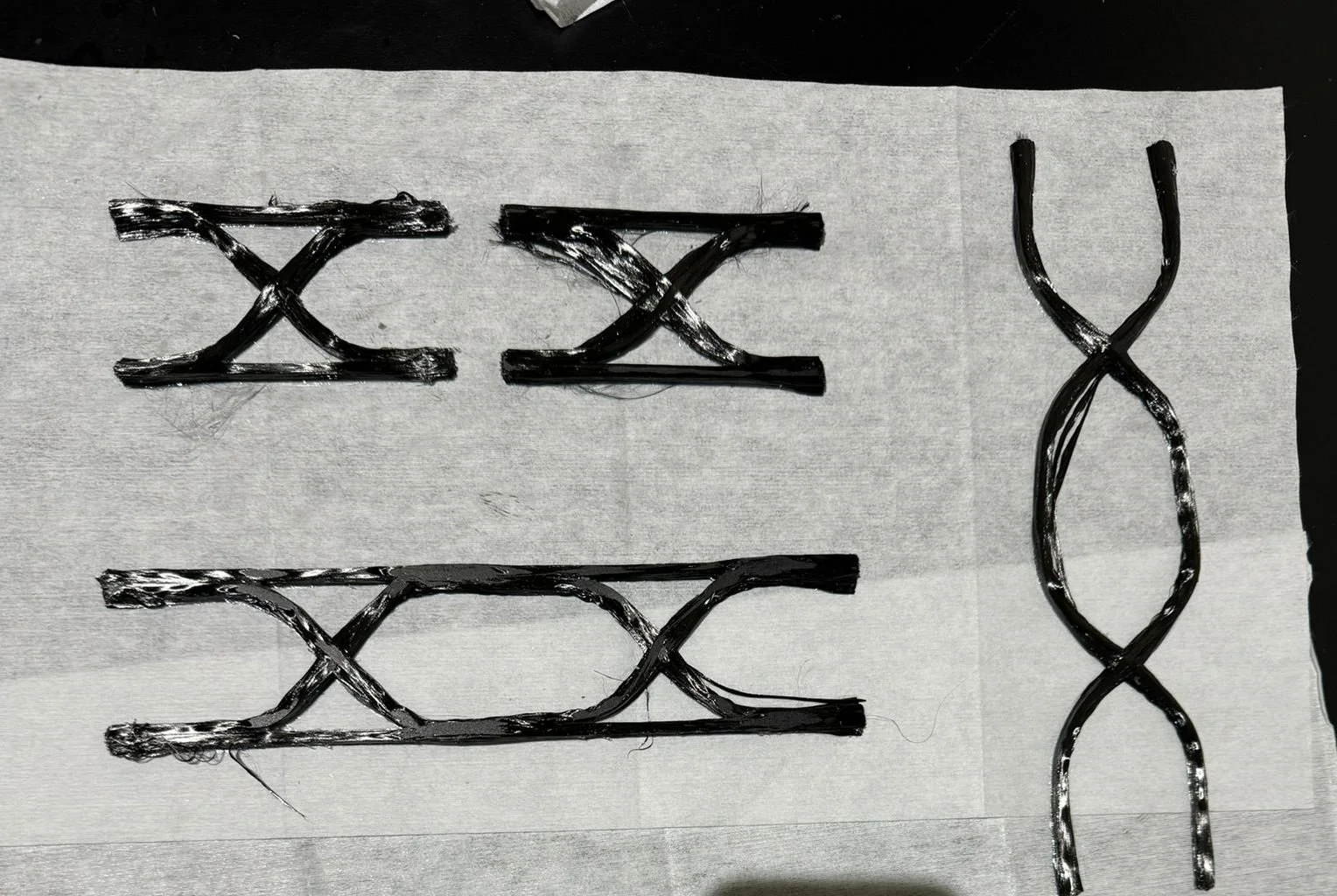

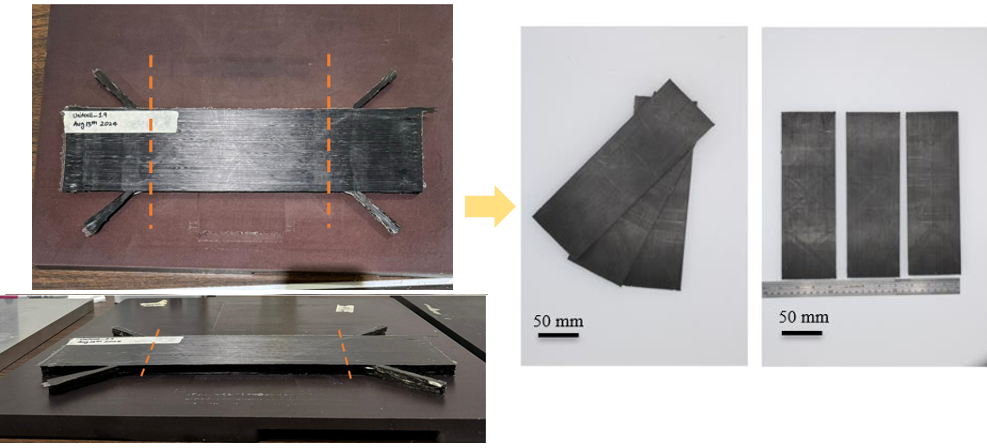

With the novel fiber print pathing and co-curing strategy, I conducted mechanical testing and FEA (ANSYS) to benchmark print-optimized sandwich composites, revealing a 260% increase in bonding quality and a 30% reduction in failure rates compared to traditional sandwich composites.

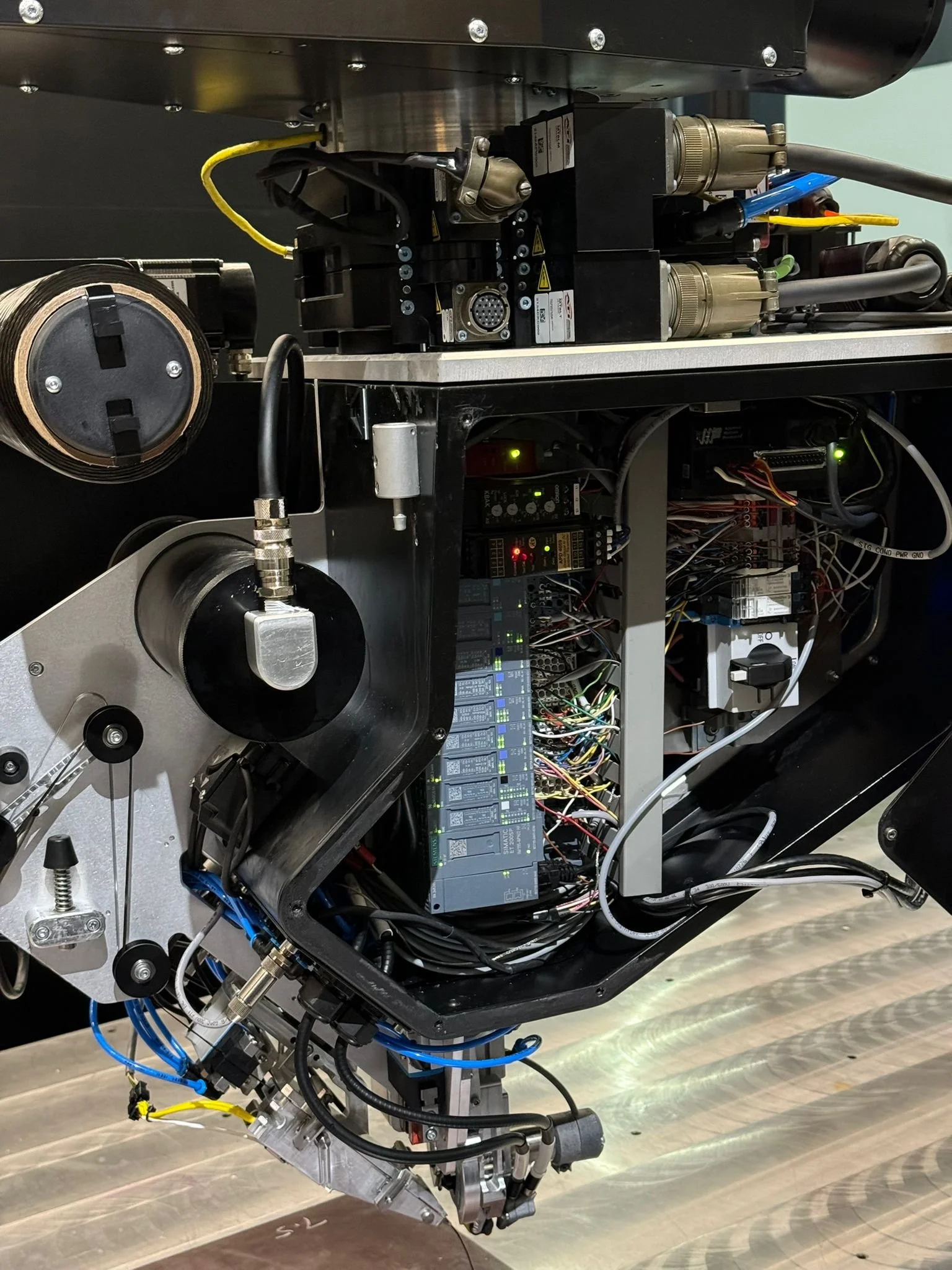

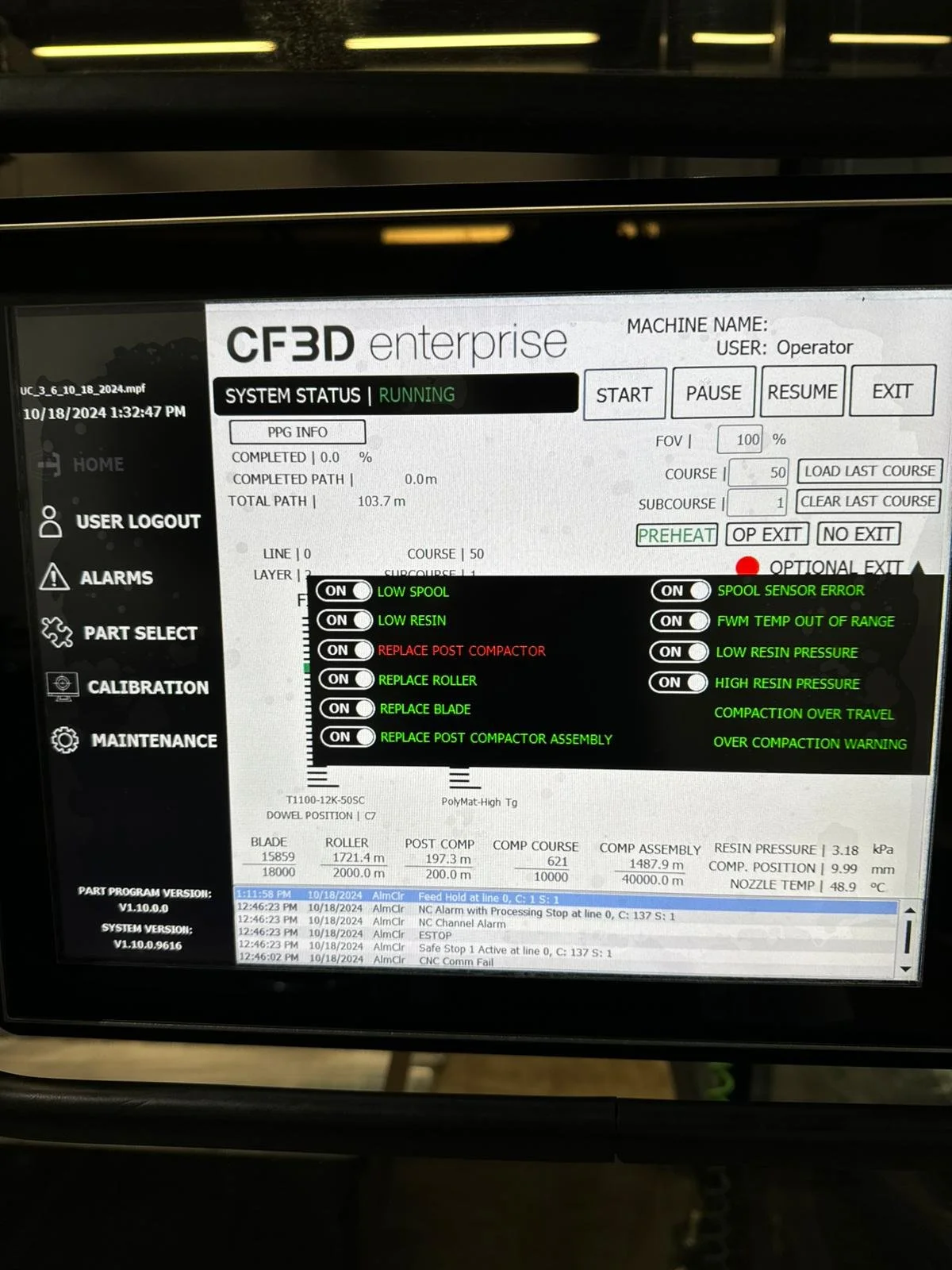

In the process, I optimized print parameters such as UV intensity for snap-cure, compaction force, and many more while also learning the CF3D robotic machine & slicing software. Furthermore, I conducted a Root Cause Analysis to identify and resolve errors with consistent quality in 3D printing, as I developed a Standard Operating Procedure (SOP) that not only minimized printer downtimes but also consistently enhanced the quality of prints.

Mechanical Research Assistant

My research and Master’s Thesis on Additive Manufacturing of composites aimed to enhance carbon fiber sandwich structures' performance using CF3D technology, focusing on optimizing fiber print layup and co-curing strategy for improved tensile and compressive strength. By identifying the best layup configurations, the study seeks to leverage additive manufacturing's advantages to produce stronger, more efficient carbon fiber composites than traditional methods.

*This research is currently under review for publication, and any unauthorized replication may constitute copyright infringement.